Manufacturing-minute

Metal Art from The Machine Shop

When working with metal, there are some interesting things that happen. And we have metal art. Check out this sample of pictures taken May 20, 2020

It’s Moving Day-Part 2

Delivery Day at Pemco

Today, May 18, 2020 Pemco gets a brand new HURCO 5-Axis Integrated Trunnion Machining Center.

Pemco would like to thank Darrin Crimi, Sales Engineer with Reynolds Machinery, for being with us on installation day.

The new machine was delivered with care to the Pemco shop.

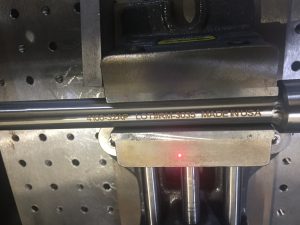

Laser Engraving

Pemco Incorporated uses laser engraving to comply with recent regulatory requirements for traceability of the medical devices we manufacture.

Recently, the United States Food and Drug Administration (FDA) and the European Commission have passed legislation for UDI or Unique Device Identification. This will require certain types of medical devices and packaging to be marked with a specifically formatted machine readable code (2D or Linear Barcode).

Manufacturers will be required to encode several pieces of data into these machine readable codes including their Device Identifier (DI) or GS1 Global Trade Item Number® (GTIN®) as well as various production or application identifiers such as batch numbers, date codes, expiry dates and serial numbers.

5-axis Versatility at Pemco

Pemco has the capability of milling a variety of of parts for our customers. The Hurco 5-axis machine, featured in this article, stays busy milling a large piece.

A Little Trip To The Pemco Shop

Pemco Incorporated was founded in 1946 and the current machine shop has been in operation since 1953. High quality craftsmanship with only the best equipment was the building block for Pemco’s established excellence in manufacturing.

In 1953, Pemco invested in top notch quality equipment, some of which are still in use today.

Here are a couple of more vintage machines.

Pemco Incorporated is well known for a long history of excellence in both our medical and industrial products. We build to make them last. Still the only way to truly keep that going is with regular care and maintenance. As you can see from the evidence, that is how we operate.

Check back for more “From the Shop” coming soon.